Praecis announces rapid-setup chamber designed to protect healthcare providers and clinical staff

April 22, 2020: As many firms are doing today, Praecis Incorporated, an ultra-precision engineering company based in Ann Arbor, Michigan, is focusing its efforts on innovating its technology to help combat the spread of COVID-19. To that end, Praecis has launched the Medical Isolation Chamber to help mitigate the spread of the coronavirus between patients, clinical staff, and healthcare providers.

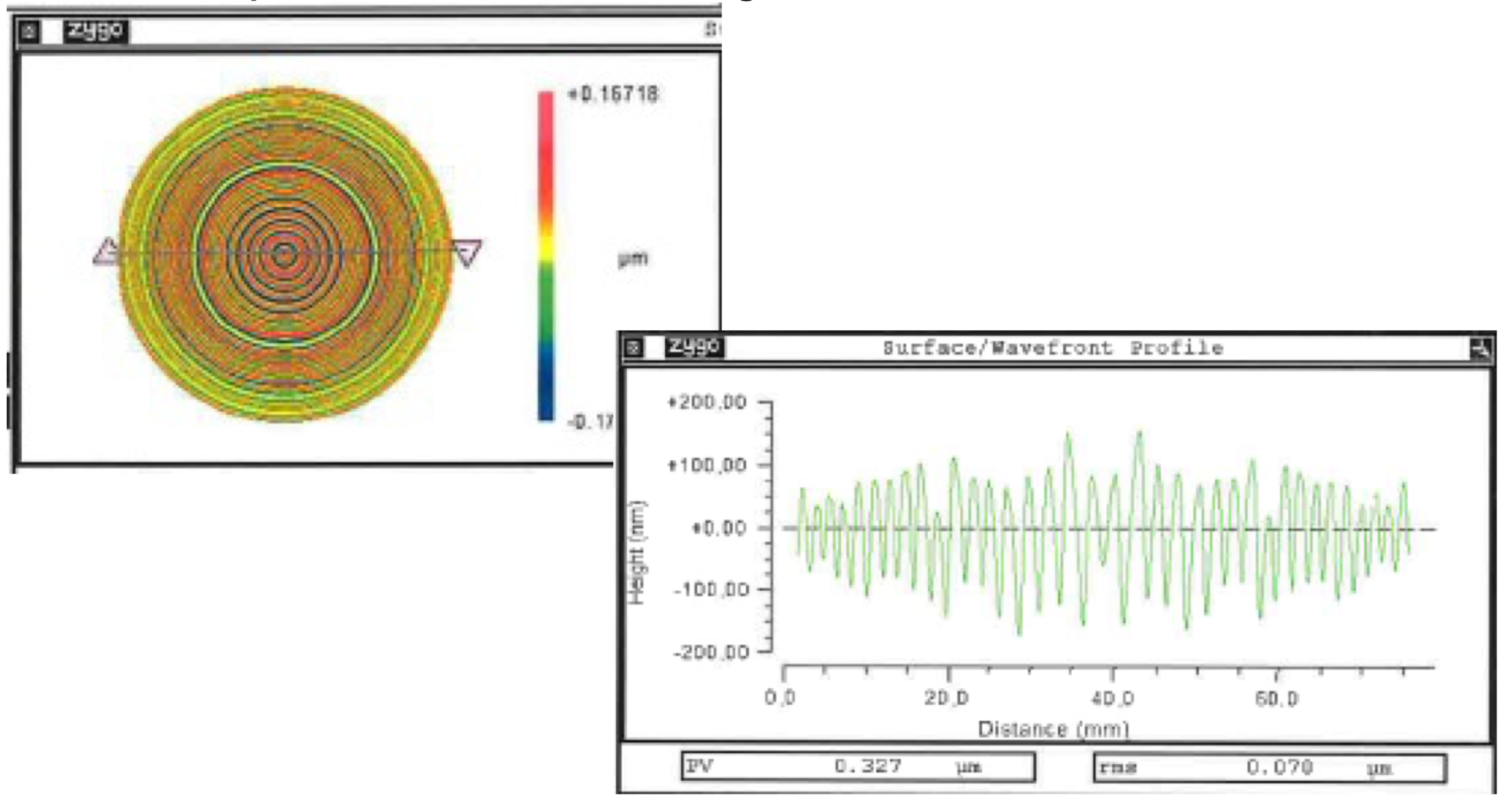

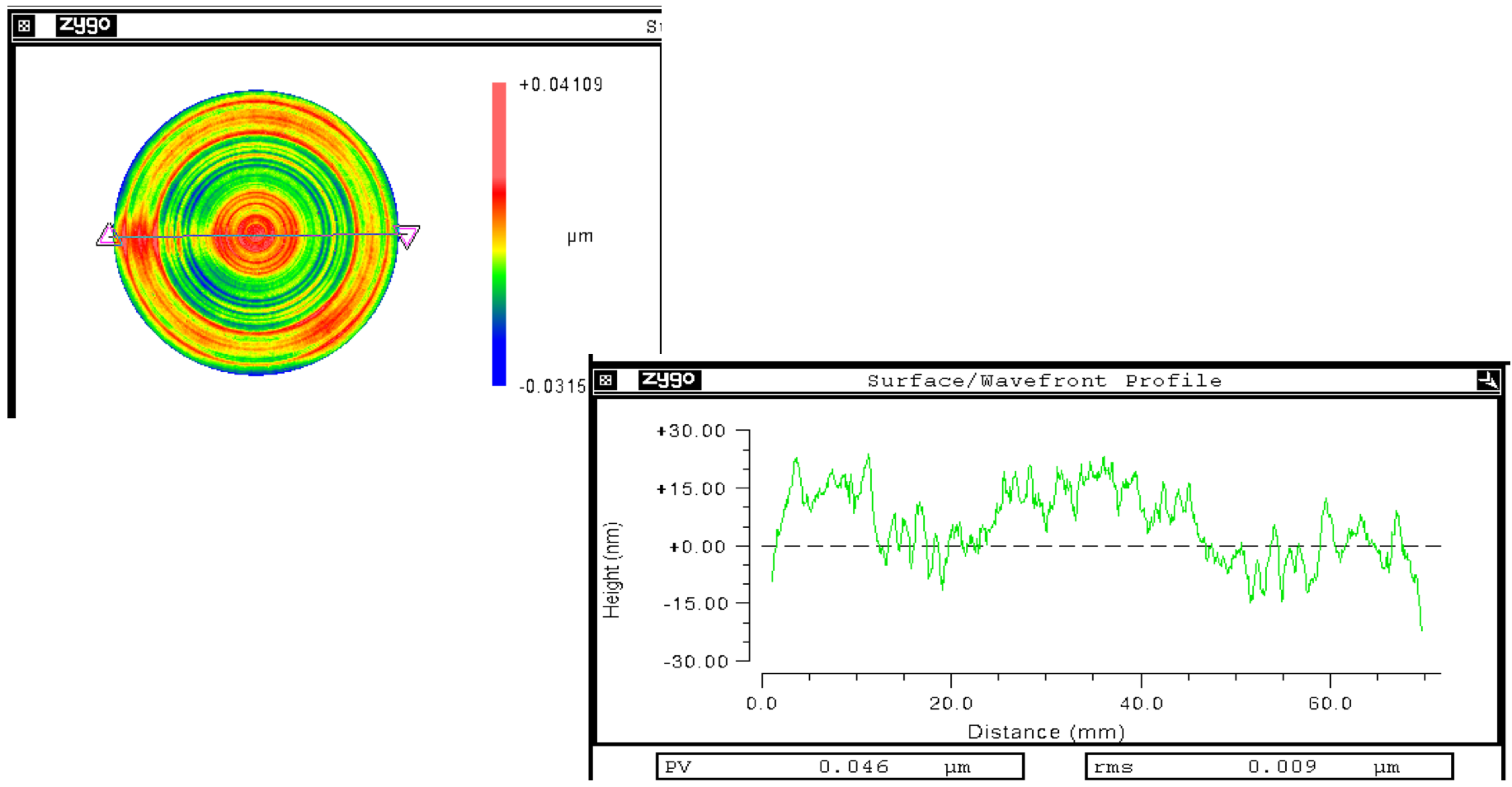

Praecis consolidated their expertise on laminar flow, from the Ultra-Precision Air Temperature Control Units they have built for several years, to innovate a new chamber that uses laminar flow airflow to carry contaminated air to a specialized sanitization unit. Praecis' unique air mattress allows for air to be exchanged from the patient medical isolation chamber up to six times per minute, thereby providing patients with fresh air while neutralizing any traces of the coronavirus along with any other forms of virus and bacteria before releasing the purified air offsite.

Being able to react quickly to the COVID-19 pandemic was critical for hospitals and first responders. Low supplies of N95 masks and other PPE continues to impact those working on the frontlines of healthcare negatively. Praecis is hoping their new biocontainment chamber will be a helpful tool in flattening the curve and protecting patients, clinical staff, and healthcare providers.

About Praecis:

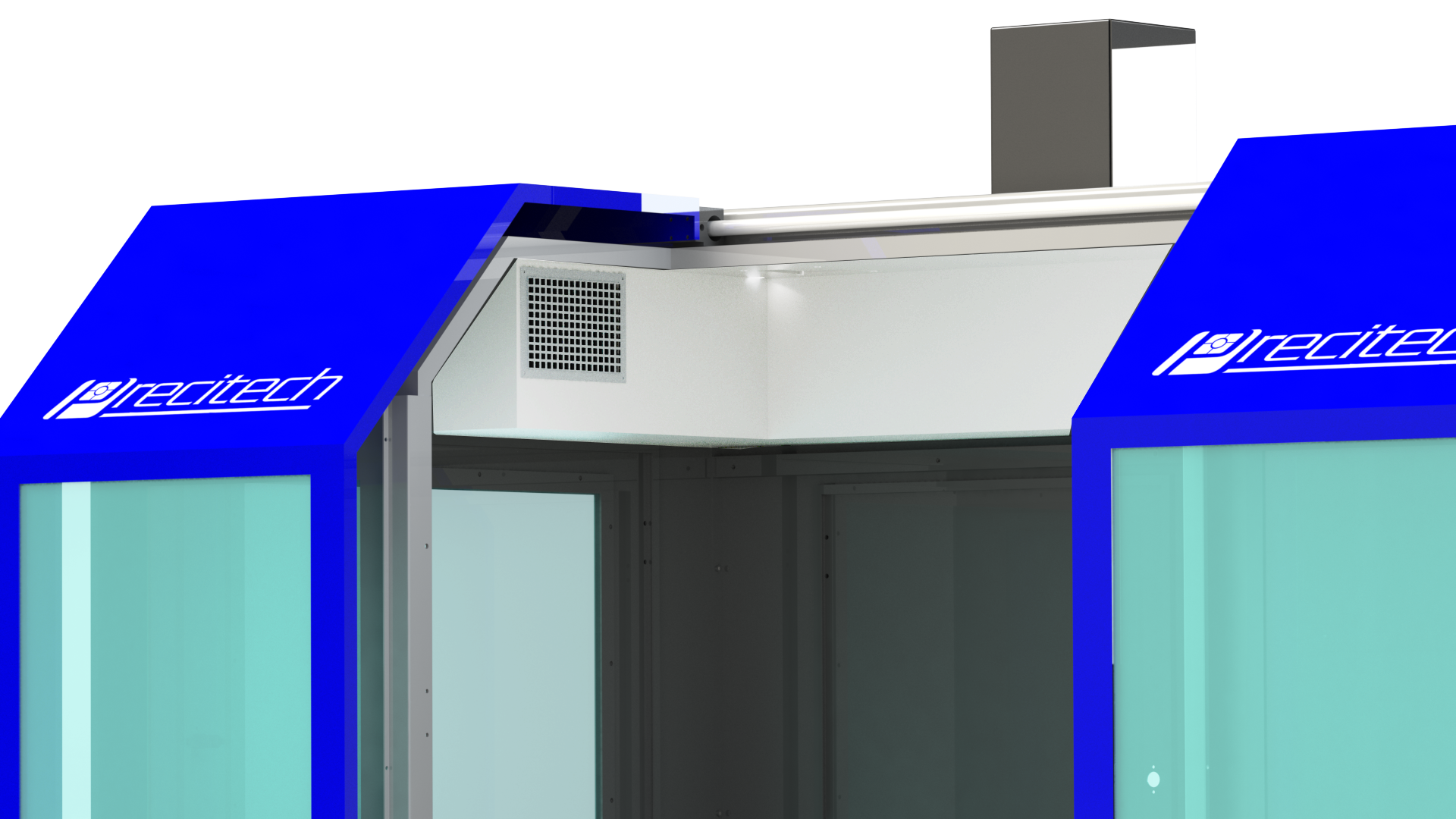

Praecis provides state-of-art environmental controls for rooms and chambers. Praecis Environment rooms control climatic conditions, including temperature, humidity, cleanliness, and pressure.

For more information, contact Susan Wayne, VP of Business.