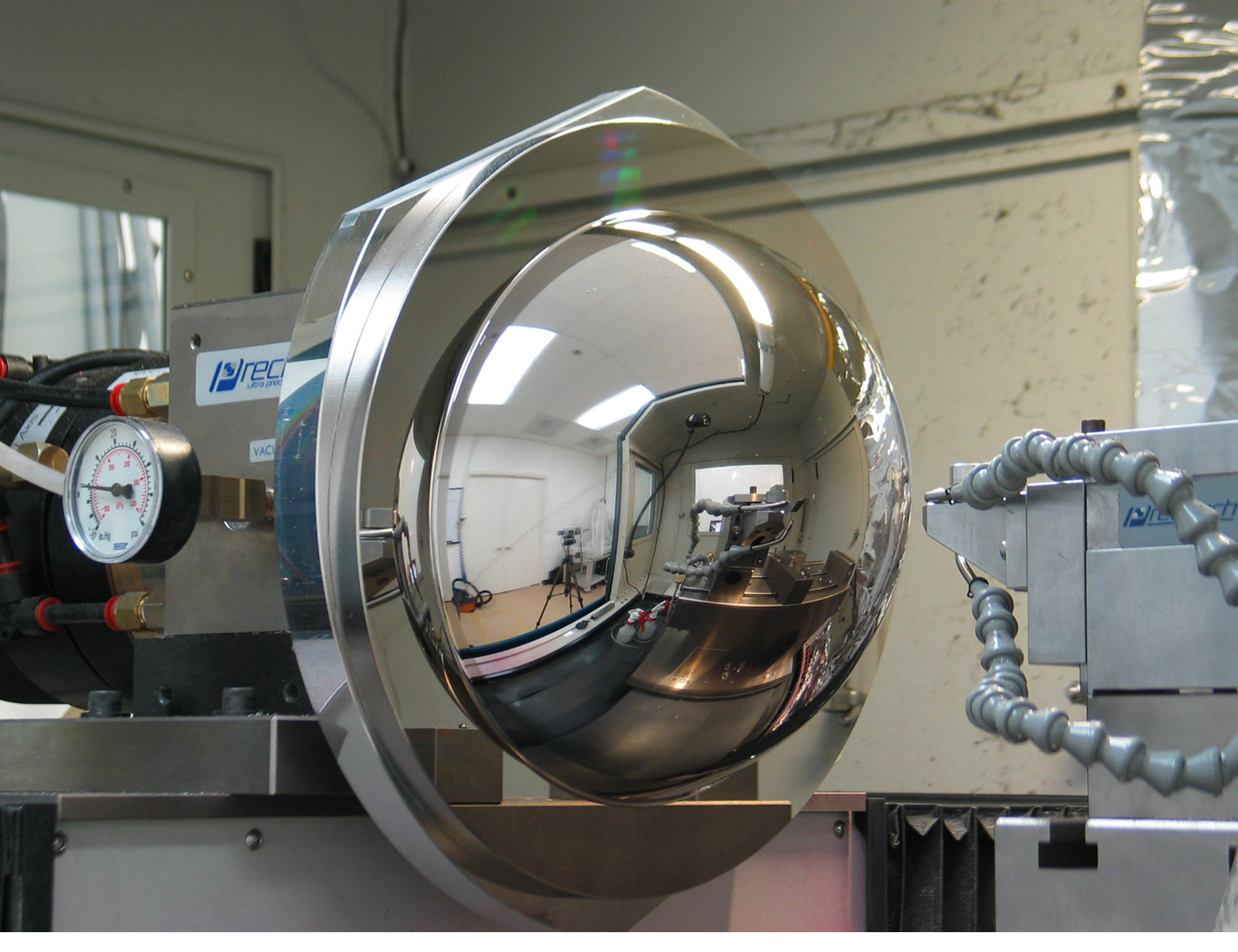

What if temperature never changed inside of a diamond turning machine / DTM?

What if the temperature could be perfectly stable to a millidegree?

These are great questions because they are only a few ways to eradicate thermal errors inside of a diamond turning machine enclosure.

By adding temperature controlled ventilation to the enclosure of a diamond turning machine, internal DTM temperature can be stabilized and errors caused by temperature variations can be proportionally decreased.

With precision air temperature control results are more accurate and repeatability increases.

There are very few products today that can eliminate error and stabilize temperature variation inside an enclosure. Many temperature control systems that exist today can control down to ±0.1 ºC. Holding ±0.1 ºC is great for some applications but it is possible to stabilize temperature to a much greater degree at a low cost.

Praecis Inc. is capable of producing a product that can stabilize temperature accurate to the millidegree at an affordable cost. Results can be as precise as ±0.002 ºC, minimizing changes to a parts dimensions due to thermal expansion. This effectively improves diamond turned parts by a factor up to 10 or greater.

Please visit the library at http://www.praecis.com/research-papers/ to learn more about how thermal effects can cause errors in diamond turning part cuts.