Everything Changes Size When the Temperature Changes.

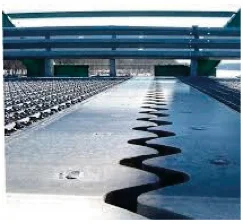

One of the most noticeable examples of thermal expansion is the spreading of joints in bridges. These joints allow for seasonal variations in the length of the bridge span as temperature vary throughout the year. In precision engineering, optics, metrology, and other ultra-precise engineering applications, small differences in size are absolutely critical.

When a material is heated the distance between individual atoms will change. For most materials the atoms get further apart and the total length change depends on how many atoms are in the length. This makes the temperature change proportional to length. For example, if a one-meter piece of metal changes length by some small amount, a two meter piece would be expected to change by twice the amount.

Changes in length is proportional to the temperature change. The constant of proportionality is called the coefficient of thermal expansion (CTE), denoted by the Greek letter alpha (a).

Predicting Thermal Expansion

Precision instrumentation is built from components of a variety of materials—which, with different CTE’s, expand and contract by different amounts with temperature changes. To further complicate the problem, different materials have different rates of thermal conductivity, making the individual instrument parts and the work piece fluctuate in size at different rates.

Because of the complexity of the system and time to execute the activity, the combined thermal changes in a precision manufacturing process are impossible to predict.

To prevent the effects of thermal expansion from harming ultra-precision measurements, Praecis Inc. has developed an ultra-precision air temperature control system. By stabilizing the air to +/- 0.003 °C from a set temperature, Praecis ATCU (Ultra Precision Air Temperature Control Unit) can virtually eliminate any thermal instabilities and makes even the slightest precision temperature control and thermal management easier.

Learn more about stabilizing the temperature of your instruments and measured parts with precision temperature control.