Thermal Drift in MBMW

Mechanical Drift vs Air Temperature Stability

The Problem:

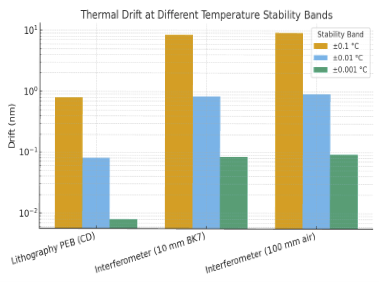

Multi-Beam Mask Writers (MBMWs) operate over many hours, often exceeding 10–20 hours per mask write. During this time, even small temperature fluctuations at the tool air intake/critical point can cause measurable deformation of the quartz mask substrate. Published SPIE studies (2014) show that global heating during long MBMW exposures results in nanometer-level mask distortion, directly impacting registration and CDU (critical dimension uniformity).

For example, at a standard cleanroom tolerance of 23 °C ±0.3 °C, a 6-inch quartz mask can expand or contract by more than ±20 nm across its edge — already exceeding placement error budgets for next-generation lithography. Even at ±0.1 °C stability, mask drift is on the order of ±7.6 nm, which cannot be ignored in sub-3 nm technology nodes.