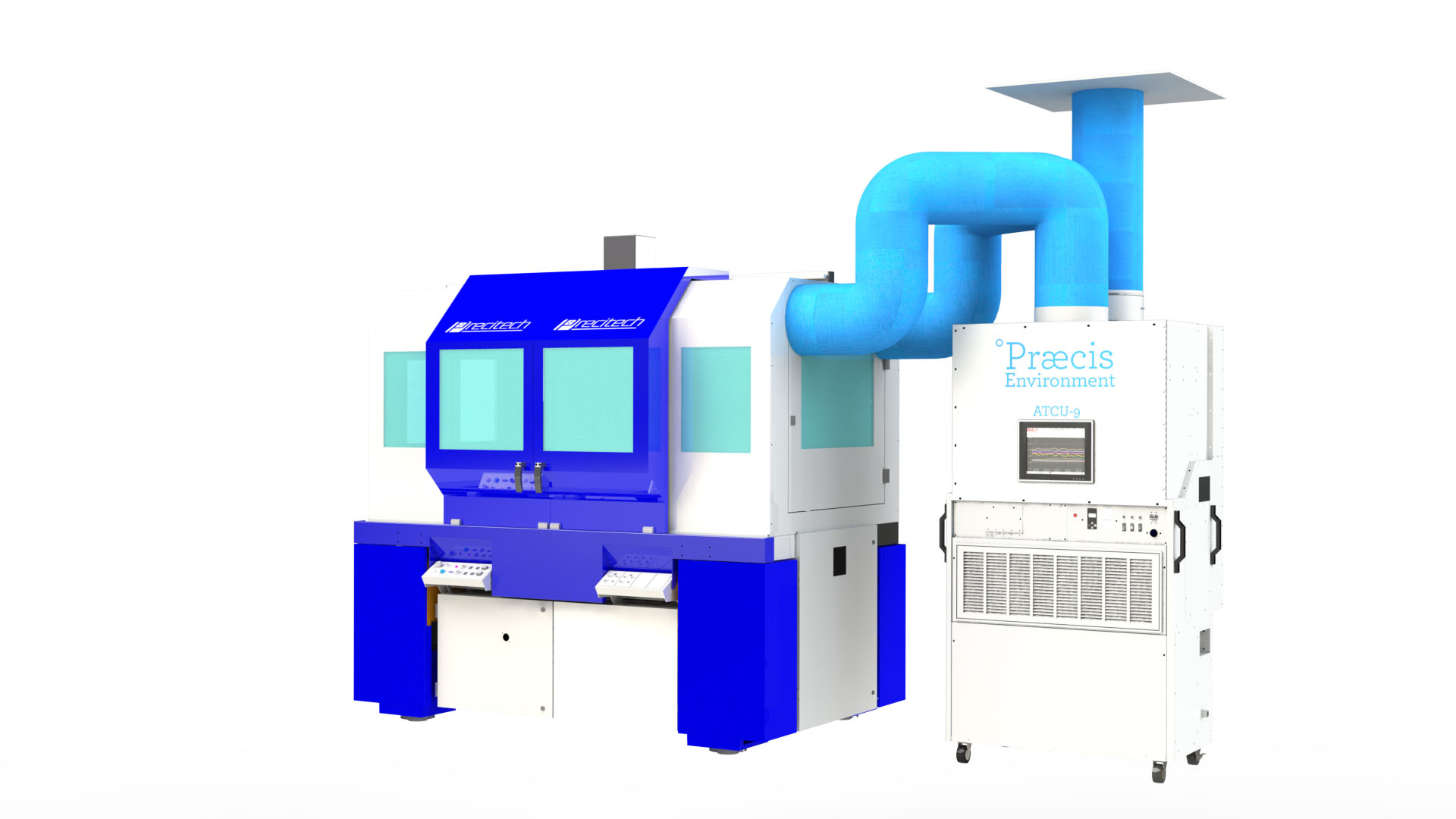

Praecis ATCU-9 Retrofit System Installation on Precitech Planoform 650 Ultra™:

Application: Precitech Planoform 650 Ultra™ Diamond Turning Machine.

Customer: n/a

See the performance report for this unit.

Temperature Control Results:

Critical Point held at 20.5 ºC +/- 0.01 ºC in a +/- 2.25 °C environment (215:1). Performs with high reliability even with frequent thermal variation in the room.

Sub-Systems:

- ATCU-9

- Existing Precitech Planoform 650 Ultra™ Diamond Turning Machine

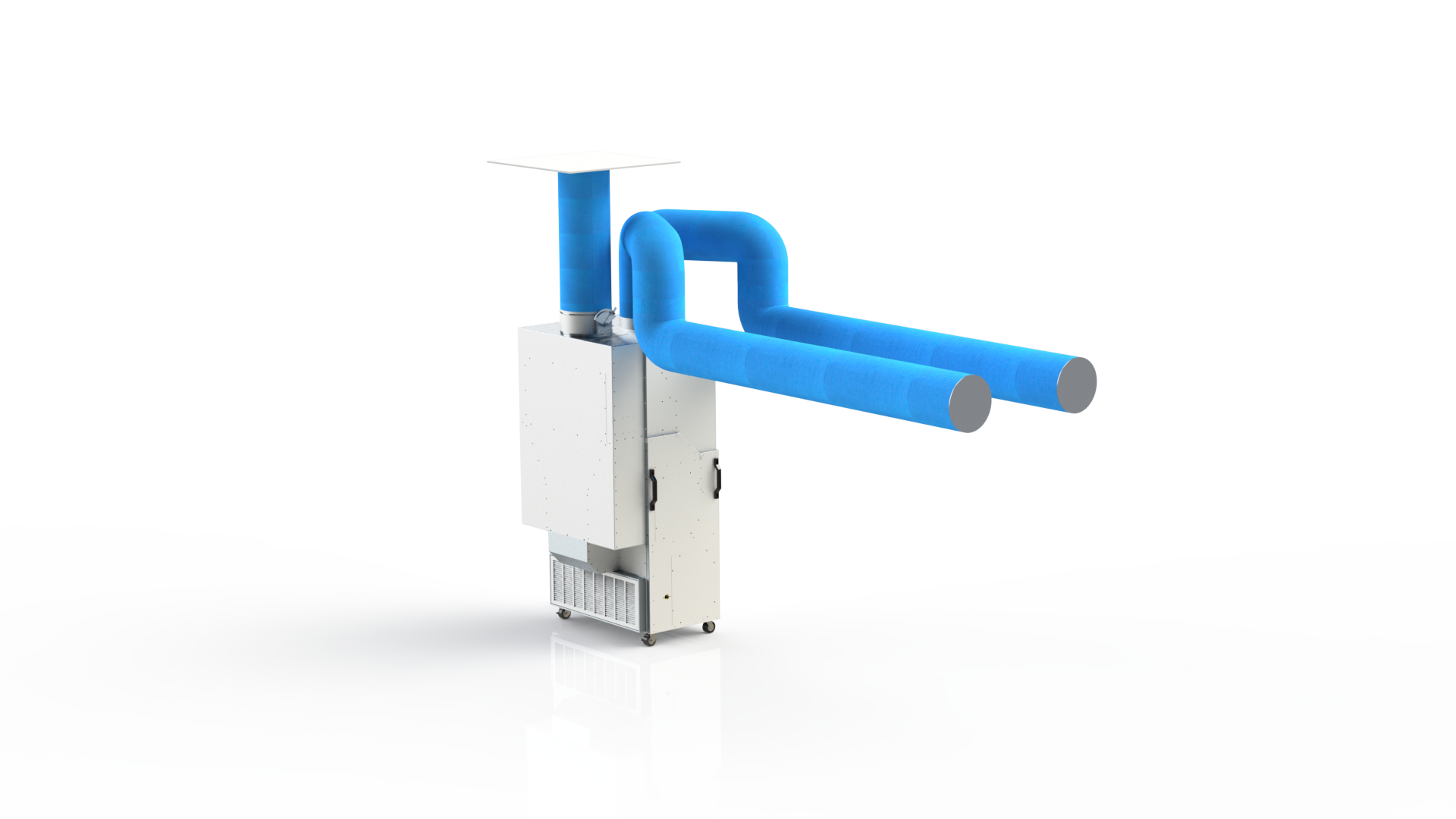

- Discrete air inlet ducts attached to the Praecis ATCU via ducting complete with porous fabric air distribution .

Enclosure Description:

- Standard Precitech enclosure with sliding doors and roof panels.

- Precitech-supplied air duct attachment. The air duct has two vents, one located on each end of the enclosure. The width of each vent is 70 mm.

- Air distribution system does not impede operator and part access.

Enclosure Size:

2 x 1.1 x 1.8 m (W x D x H) (Inside dimensions.)

Footprint: 2.2 m²

Volume: 3.96 m³

Air Velocity: 0.41 m/sec

Comments:

By using a Praecis ATCU-9 with the Precitech Planoform 650 Ultra™, the ATCU is able to offer a greater range of air flow rates to cool the part to the desired temperature during operation. The ATCU-9 is then moved for operation on a different much larger system after use.

Praecis ATCU-9 retrofit system on a Precitech Planoform 650 Ultra.

Praecis ATCU-9 Porous Fabric Air Distribution System.

Praecis ATCU-9 being prepared for shipment.

Performance Chart of the ATCU-9 Room versus Critical Point